The Differences in Mild Steel, Tool Steel and Stainless Steel

Steel, in the most basic terms, is refined elemental iron mixed with carbon to form a stronger material. However, there are thousands of different forms of steel, as it is a chemical process with dozens of possible chemicals added for specific properties.

At the foundry different chemicals are added to steel for specific properties.

Despite the wide range of different compositions, steel can be categorized into one of three basic families: stainless steels, tool steels, and mild or low-carbon steel.

Chemistry

The most defining difference between tool, mild and stainless steel is the chemical makeup of the steel. Generally, mild steels are simple steels with very few elemental additives. Tool steels are tailored for specific properties using multiple additives, and stainless steels have very large concentrations of one or two elements. Carbon is perhaps the most critical chemical additive, since it directly determines the hardenability of steel. Mild steels typically contain less than 1 percent carbon by mass; tool steels can contain up to 15 percent or more carbon, as do stainless steels. Stainless steels contain up to 20 percent chromium and relatively high concentrations of nickel, chemicals not typically added to mild or tool steels. Tool steels can contain multiple additives in trace amounts or in higher concentrations. These elements determine specific physical and mechanical properties.

Physical Properties

A steel's physical properties are determined by its chemistry. Generally, mild steels have moderate toughness and are quite easy to weld, due to their simple composition, but are prone to corrosion. Stainless steels and moderate to difficult to weld, due to their complex composition, but are very resistant to corrosion. Tool steels have excellent machinability, hardenability and wear resistance, but can be prone to corrosion.

Hardenability

The hardenability, or ability to turn steel from malleable to hard, is determined by the carbon content, and to a lesser extent, trace elements. As a rule, mild steels are generally not able to be hardened, since they contain so little carbon. Some stainless steels can be hardened, but not every form of stainless steel has this ability. Nearly all tool steels can be hardened, but with the use of different mediums. Some need to be quenched in oil or water to be properly hardened, while others are able to harden in the air after proper heat treatment.

Uses

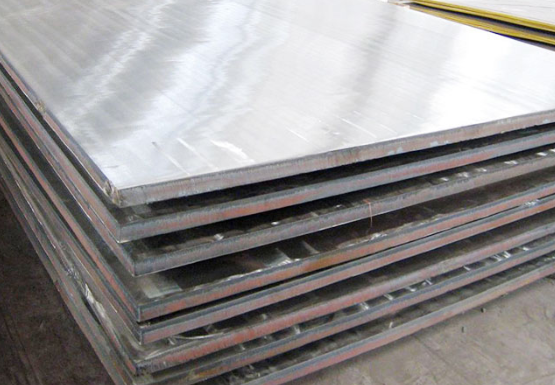

Mild steels are generally the cheapest steels, and the ones made in the greatest abundance. They are used as structural materials, and as sheeting in building trades. Stainless steels are used in finished products, like food service materials or as a cladding, where corrosion resistance is necessary. Tool steel is used almost exclusively in machining and tool making, though some cutlery is also made from certain grades.

Suggested reading:Minerals & Metallurgy

The Drip Cap

How to Choose Stainless 304?

Nickel Strip VS Steel Strip

Is copper composite steel the future of construction?

The Ultimate Guide to Pre-Painted Galvanized Steel

Ultimate Guide to Titanium Steel Composite: Benefits, Uses & FAQs

The Ultimate Guide to Cladding Armor Trends

Steel, in the most basic terms, is refined elemental iron mixed with carbon to form a stronger material.

Generally, mild steels are simple steels with very few elemental additives.

Stainless steels contain up to 20 percent chromium and relatively high concentrations of nickel, chemicals not typically added to mild or tool steels.

Generally, mild steels have moderate toughness and are quite easy to weld, due to their simple composition, but are prone to corrosion.

Mild steels are generally the cheapest steels, and the ones made in the greatest abundance.

Kingsdun is a precision screwdriver manufacturer, if you are looking for a Chinese screwdriver manufacturer, please contact us, we will give you the most sincere advice, thank you

Here is a basic link explaining tool steels:

A lot of carbon steel is easier for makers to work with, keeping the cost down. You see lots of nice knives in basic carbon steels on the exchange for cheap. Tool steels are just carbon steels developed for industrial tooling and are very tough and take a good edge. D2 is a great steel because it has good wear resistance and doesn't rust as easily as O1 or 1095, but it is a bit harder to sharpen. Tool steels are some of my favorite steels A2, D2, O1 and are carefully manufactured for specific purposes and sometimes make good knife steels. I like good stainless as well, but it is more expensive and a bit harder to sharpen in my experience. You get a trade off in wear resistance (edge holding). Modern super stainless is every bit as good or better than "tool"steel or basic carbon steel, but much more expensive. A lot of people are willing to deal with rust issues to get good performance of carbon steels, but as some of the Oregonians have stated, 1095 or O1 is a pain in the butt to take care of in coastal regions.Here is a basic link explaining tool steels: http://en.wikipedia.org/wiki/Tool_steel

The Differences in Mild Steel, Tool Steel and Stainless Steel

Stainless Steel vs. Carbon and Tool Steel; What Makes the Difference?

Suggested reading:Understanding the Composition of Tungsten Carbide Rod

What Are Wear Plates Used For?

What To Consider When Choosing Business Trash Cans

Sintered Porous Metal Stainless Steel Discs: Versatile and Reliable

What are soft magnetic alloys?

How Flexible is Tungsten Wire?

Benjamin Moore Black Paint