Advantages of Stainless Steel Wire Rope Mesh for Marine Applications

Wire Rope Mesh, a marvel of engineering and design, stands as a versatile and indispensable material in various industries, particularly in the challenging domain of marine applications. Among the array of materials available, stainless steel wire rope mesh has emerged as a formidable choice for maritime use. Its unique properties and advantages make it a favored solution for addressing the demanding conditions posed by marine environments. In this article, we delve into the distinct advantages that stainless steel wire rope mesh offers for marine applications, shedding light on why it is the material of choice for the high seas.

Stainless steel wire rope mesh, with its exceptional corrosion resistance, stands as an ideal candidate for maritime use. The harsh and corrosive nature of the marine environment, characterized by the relentless exposure to saltwater and the elements, necessitates materials that can endure these conditions without succumbing to rust or corrosion. Stainless steel, as the base material, possesses inherent resistance to corrosion, ensuring the mesh remains robust and functional even when exposed to the corrosive marine atmosphere for extended periods.

Moreover, the durability and longevity of stainless steel wire rope mesh contribute significantly to its suitability for marine applications. The material's inherent strength and resilience enable it to withstand the stresses imposed by the dynamic marine environment. From withstanding the forces of waves and winds to enduring the constant movement and vibration experienced on a vessel, stainless steel wire rope mesh remains structurally intact over time, minimizing maintenance efforts and costs.

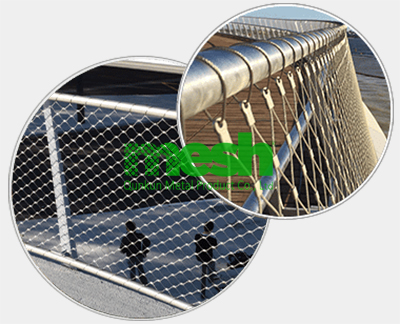

A key advantage of stainless steel wire rope mesh in marine settings lies in its adaptability to varying conditions. Vessels and marine structures often encounter changing environmental conditions, including temperature fluctuations, strong currents, and high winds. The material's flexibility and ability to accommodate these dynamic circumstances make it an excellent choice for applications such as safety enclosures, balustrades, and containment systems. The mesh retains its integrity, offering consistent performance and protection irrespective of the environment's challenges.

Additionally, stainless steel wire rope mesh contributes to the overall aesthetic appeal of marine environments. Modern marine architecture emphasizes design and aesthetics alongside functionality and safety. Stainless steel wire rope mesh offers a sleek and contemporary aesthetic, enhancing the visual appeal of vessels, ports, and maritime structures. Its clean lines, transparency, and ability to reflect and transmit light make it a favored choice among architects and designers aiming to achieve a modern, sophisticated look in marine design.

In conclusion, stainless steel wire rope mesh stands as a material of choice for marine applications, embodying a perfect amalgamation of durability, adaptability, safety, and aesthetic appeal. Its resistance to corrosion, durability, adaptability to dynamic conditions, safety features, and aesthetic qualities make it a formidable asset in the challenging and ever-changing world of the high seas. As maritime technology and design continue to evolve, stainless steel wire rope mesh will undoubtedly play an increasingly pivotal role in shaping the future of marine applications.

Custom Stainless Steel Security Mesh vs. Traditional Security Grilles

different advantages of different stainless steel wire rope mesh types

Stainless steel wire rope mesh is made of high-quality stainless steel and is a fabric with special elasticity and flexibility. It was invented in 2000 and opened up a new world of spatial possibilities using wire rope. It is no wonder that stainless steel wire rope mesh has quickly swept the global market due to its high strength, durability and corrosion resistance. The weaving type is divided into two major series: Stainless Steel Wire Rope Woven Mesh and Stainless Steel Rope Ferrule Mesh type

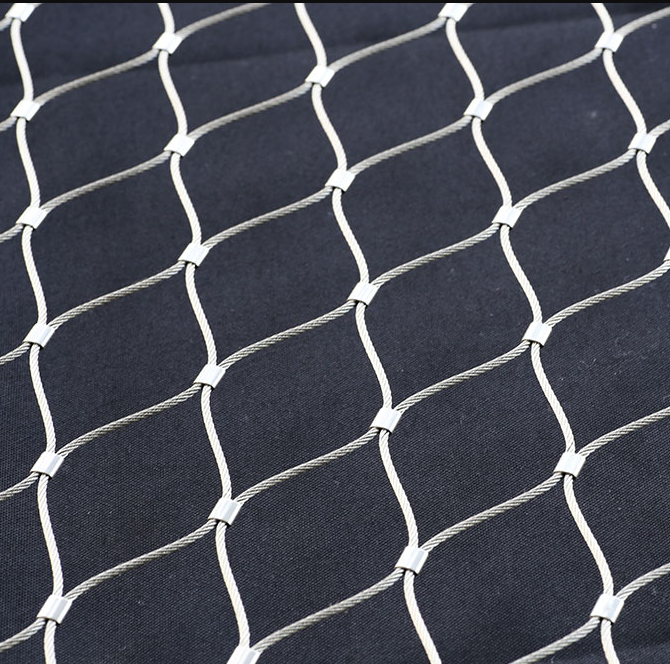

Stainless Steel Rope Ferrule Mesh

Stainless Steel Rope Ferrule Mesh is suitable for animal fences, railings, safety fences, ceilings, etc. Stainless Steel Rope Ferrule Mesh is made of parallel stainless steel cables connected with stainless steel ferrules or sleeves. Stainless Steel Rope Ferrule Mesh has a more beautiful appearance. Therefore, Stainless Steel Rope Ferrule Mesh is more suitable for decoration. It is often used as railing filler, stair railings, safety nets. In addition to its beauty, Stainless Steel Rope Ferrule Mesh can also provide safety for people and animals.

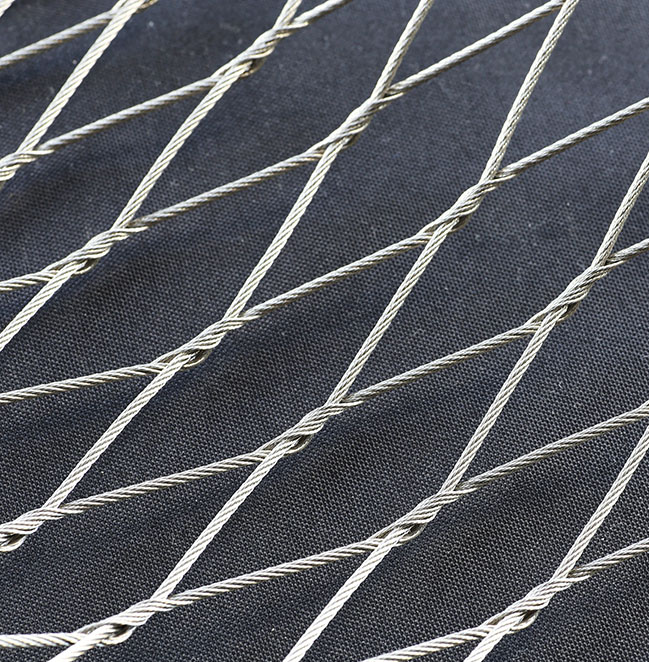

Stainless Steel Wire Rope Woven Mesh

Stainless Steel Wire Rope Woven Mesh is a diamond mesh with high flexibility and toughness, ideal for railings, zoo fencing and exterior greening.

Stainless Steel Wire Rope Woven Mesh is made of multiple pairs of parallel steel wire ropes connected to each other by braided knots. The wire rope woven mesh is very transparent and has a simple but tight structure, so most zoos and aviaries prefer Stainless Steel Wire Rope Woven Mesh. Especially Stainless Steel Wire Rope Woven Mesh is lighter than Stainless Steel Rope Ferrule Mesh.

Our stainless steel wire rope mesh is made of high-strength stainless steel AISI 304, 304L, 316 or 316L. At the same time, these cables are available in 7 × 7, 7 × 19 or 1 × 19 structures, with diameters ranging from 1.2 mm to 4 mm. We can also manufacture other specifications to meet your design requirements.