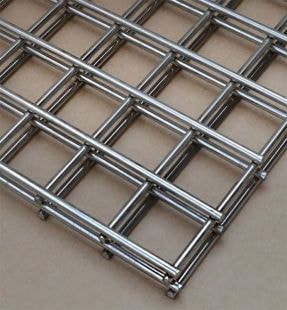

Is Welded Wire Mesh Galvanized? What is Welded Wire Mesh Made Of?

Yes, welded wire mesh can be galvanized. Galvanization is a process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. When welded wire mesh undergoes galvanization, it becomes more durable and resistant to environmental factors such as moisture, humidity, and exposure to the elements. This makes galvanized welded wire mesh suitable for a wide range of applications, including fencing, construction, agriculture, and industrial uses.

What is Welded Wire Mesh Made Of?

Welded wire mesh is typically made of steel wire that is welded together to form a grid pattern. The type of steel used can vary depending on the intended application and specific requirements. Common types of steel wire used in welded wire mesh include low carbon steel, stainless steel, and galvanized steel.

Low Carbon Steel

Low carbon steel wire is one of the most commonly used materials for welded wire mesh. It is economical, easy to work with, and offers good strength and durability. Low carbon steel wire is suitable for a wide range of applications, including fencing, animal enclosures, concrete reinforcement, and general industrial uses.

Stainless Steel

Stainless steel wire is highly resistant to corrosion, making it ideal for applications where exposure to moisture or harsh environments is a concern. Stainless steel welded wire mesh is commonly used in marine environments, food processing facilities, pharmaceuticals, and architectural applications where aesthetics and hygiene are important.

Galvanized Steel

Galvanized steel wire is coated with a layer of zinc through a process called galvanization. This coating provides an additional layer of protection against rust and corrosion, making galvanized welded wire mesh suitable for outdoor applications and environments with high humidity or exposure to corrosive substances. Galvanized welded wire mesh is commonly used in fencing, agricultural applications, construction, and infrastructure projects.

Suggested reading:Minerals & Metallurgy

Real-Life Applications of Welded Wire Mesh

Fencing

Benefits and Applications of Epoxy Coated Wire Mesh

The Benefits of Titanium Clad Plates Explained

1. The Ultimate Guide to Choosing a Stainless Steel Skin Plate2. 5 Reasons Why Stainless Steel Skin Plates are Superior3. Unveiling the Mysteries of Stainless Steel Skin Plates4. How to Install and Ma

Difference Between Quartz Powder and Silica Fume

Ultimate Guide to Petrochemical Titanium Clad Plates: FAQs Answered

Exploring Petrochemical Applications of KLScladmetal Plates

One of the most common applications of welded wire mesh is in fencing. Galvanized welded wire mesh is widely used for perimeter fencing, security fencing, and animal enclosures due to its durability, strength, and resistance to rust and corrosion. It provides a cost-effective solution for securing residential, commercial, and industrial properties while allowing for visibility and airflow.

Concrete Reinforcement

Welded wire mesh is often used as reinforcement in concrete structures to improve their strength, stability, and durability. The mesh is placed within the concrete slab or wall during the pouring process to help distribute the load and prevent cracking. Galvanized welded wire mesh is preferred for concrete reinforcement applications as it resists corrosion and extends the lifespan of the structure.

Agricultural Uses

In agriculture, welded wire mesh is used for a variety of purposes, including animal cages, poultry enclosures, garden fencing, and trellising. Galvanized welded wire mesh is ideal for agricultural applications due to its resistance to rust and corrosion, making it suitable for outdoor use in farm environments. It provides a secure and durable solution for containing animals, protecting crops, and supporting climbing plants.

Industrial and Construction Uses

Welded wire mesh finds numerous applications in the industrial and construction sectors. It is used for safety barriers, machine guards, shelving, partitions, and conveyor belts. Galvanized welded wire mesh is preferred for these applications due to its strength, durability, and resistance to corrosion, chemicals, and abrasion. It provides a versatile and cost-effective solution for various industrial and construction needs.

Conclusion

In conclusion, welded wire mesh can be galvanized to enhance its durability and resistance to rust and corrosion. It is typically made of steel wire and is available in various types, including low carbon steel, stainless steel, and galvanized steel. Welded wire mesh finds a wide range of applications in fencing, concrete reinforcement, agriculture, and industrial uses. Galvanized welded wire mesh is particularly suitable for outdoor and corrosive environments, providing a cost-effective and reliable solution for various real-life applications.

Top Trends in Oil Titanium Clad Plates 2024

How Should We Evaluate Oil Titanium Clad Plates?

Key Questions to Consider When Selecting E2 Steel Clad Plate

How to Choose E2 Steel Clad Plate?

Top Benefits of Choosing Stainless Steel Sheet Suppliers Today

Discover the Benefits of Safe Stockpot Composite Cookware

Why Copper Clad Steel Coils Are Game-Changers?

- Previous: Benefits and Applications of Epoxy Coated Wire Mesh

- Next: None